Hand Safety First

HSF PipeGuider Tool

HSF PipeGuider Tool

Safe Pipe Handling Made Simple

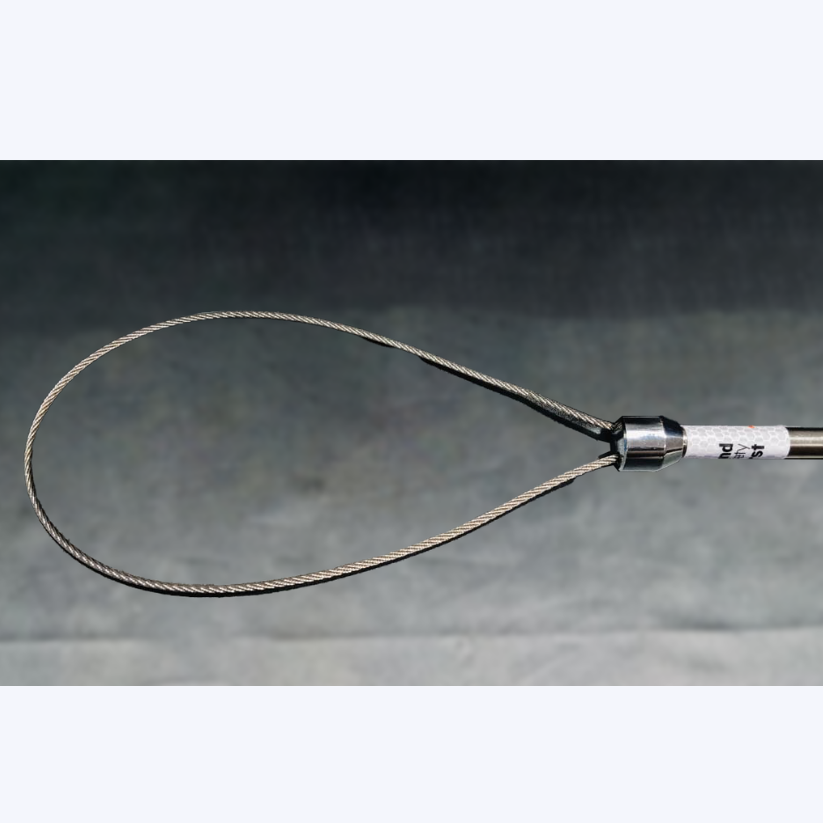

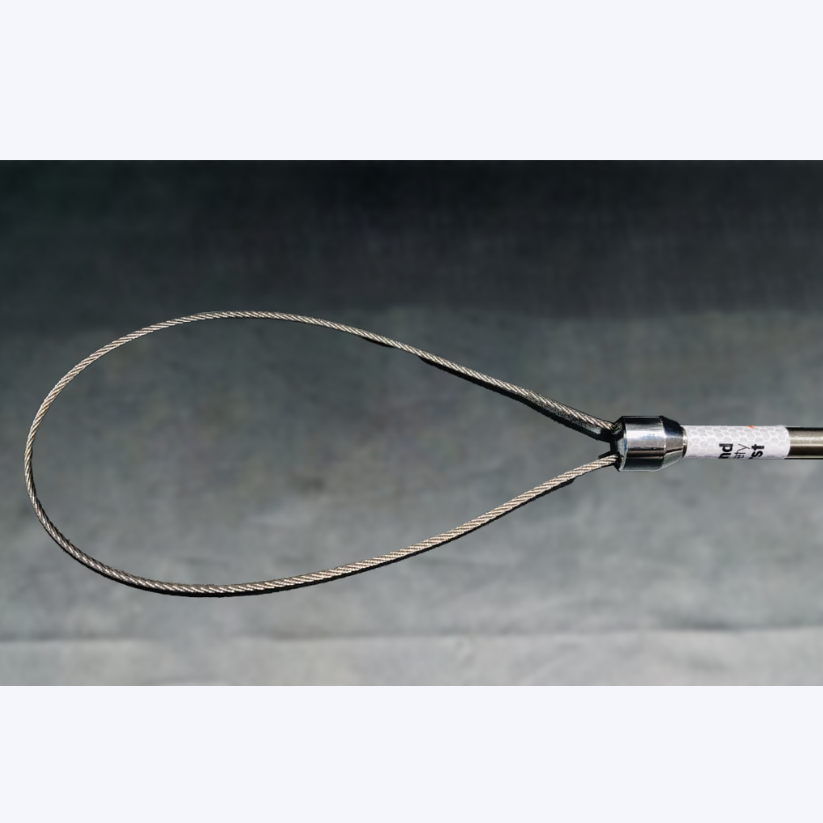

The HSF PipeGuider Tool is an advanced hands-free safety device engineered for guiding and controlling pipes and cylindrical objects during lifting, moving, and alignment tasks. Built as part of the HSF RiggerSafe range, this tool reflects our commitment to reducing workplace injuries by keeping workers’ hands at a safe distance from high-risk operations.

Every year, thousands of workers suffer hand and finger injuries due to unsafe manual pipe handling. Pinch points, crush zones, and uncontrolled pipe movement are common hazards in industries like oil & gas, shipyards, steel plants, construction, and power generation. The PipeGuider Tool eliminates these risks with a simple yet powerful noose-and-lock design that gives workers total control—without ever touching the pipe.

Share

Key Benefits

- Safer Operations: Keeps workers at a safe distance, preventing “caught between” and crush injuries.

- Wide Compatibility: Handles pipes and cylindrical objects between 2.5” and 8” (63mm – 203mm).

- Ease of Use: Quick-lock noose system for fast securing and release of pipes.

- Operator Comfort: Lightweight design with ergonomic grip reduces fatigue during long operations.

- Durability: Made with high-strength steel alloy and corrosion-resistant coating for harsh industrial environments.

- Versatility: Suitable for pipe guiding, spool alignment, lifting support, and handling cylindrical objects in multiple industries.

How It Works

Using the HSF PipeGuider Tool is straightforward:

- Loosen the noose using the built-in handle.

- Insert the noose over the pipe or cylindrical object.

- Pull the handle down to tighten the noose securely around the object.

- The locking mechanism automatically engages, ensuring a firm grip and stable control.

This intuitive design ensures workers can quickly secure and maneuver pipes without fumbling or losing control, even when wearing heavy-duty gloves.

Technical Specifications

- Pipe Handling Capacity: 2.5” – 8” (63mm – 203mm)

- Material: High-strength steel alloy with anti-corrosion powder-coated finish

- Handle: Ergonomic, non-slip grip for maximum control

- Noose Mechanism: Adjustable, self-tightening lock system

- Tool Weight: Lightweight (~3–5 kg depending on model) for easy portability

- Design Compliance: Conforms to ANSI / OSHA hands-free safety tool guidelines

- Customization Options: Available in multiple handle lengths for different site requirements

Applications Across Industries

The HSF PipeGuider Tool is engineered to serve multiple high-risk industrial environments, including:

- Oil & Gas Rigs: Pipe spool alignment, riser handling, drill pipe guiding.

- Construction: Safe pipe rolling, alignment for welding and fitting.

- Shipyards & Ports: Maneuvering heavy cylindrical loads in confined spaces.

- Steel Plants & Power Plants: Guiding pipes and cylindrical materials in high-temperature environments.

- Mining Operations: Safe handling of cylindrical components and heavy loads.

Why Choose HSF PipeGuider Tool?

Unlike traditional manual pipe handling, which exposes workers to crushing and impact hazards, the HSF PipeGuider Tool creates a safe buffer zone between the worker and the load.

By investing in the PipeGuider Tool, industries benefit from:

- Reduced workplace injuries → Lower downtime and compensation costs

- Higher productivity → Faster, safer pipe alignment and guiding

- Improved compliance → Meets safety regulations and company standards

- Worker confidence → Employees feel safer handling pipes, leading to smoother operations

Conclusion

The HSF PipeGuider Tool is more than just a guiding device—it’s a safety-first solution engineered for today’s toughest industrial challenges. By combining simplicity, strength, and hands-free safety, it protects workers, enhances productivity, and ensures compliance with global safety standards.