Hand Safety First

HSF RiggerSafe – Hands-Off Load Control Stick

HSF RiggerSafe – Hands-Off Load Control Stick

The HSF RiggerSafe – Hands-Off Load Control Stick is more than just a safety accessory—it's a critical tool that transforms how riggers interact with suspended loads. Crafted for the most demanding industrial environments, RiggerSafe allows workers to push, pull, and guide loads from a safe distance, eliminating the need for direct hand contact and dramatically reducing the risk of crush, pinch, or impact injuries.

Whether you're working under a suspended beam, positioning a heavy pipe, or aligning components during a critical lift, the RiggerSafe Load Control Stick gives your crew the confidence and control they need—without ever compromising on safety.

Share

What is the HSF RiggerSafe – Hands-Off Load Control Stick?

It’s an industrial-grade push/pull tool engineered for environments where traditional manual rigging poses a safety risk. Its rugged fibreglass shaft, ergonomic handle, and wide-face push head let workers guide loads precisely—without ever having to physically touch them.

Key Features of

HSF RiggerSafe – Hands-Off Load Control Stick

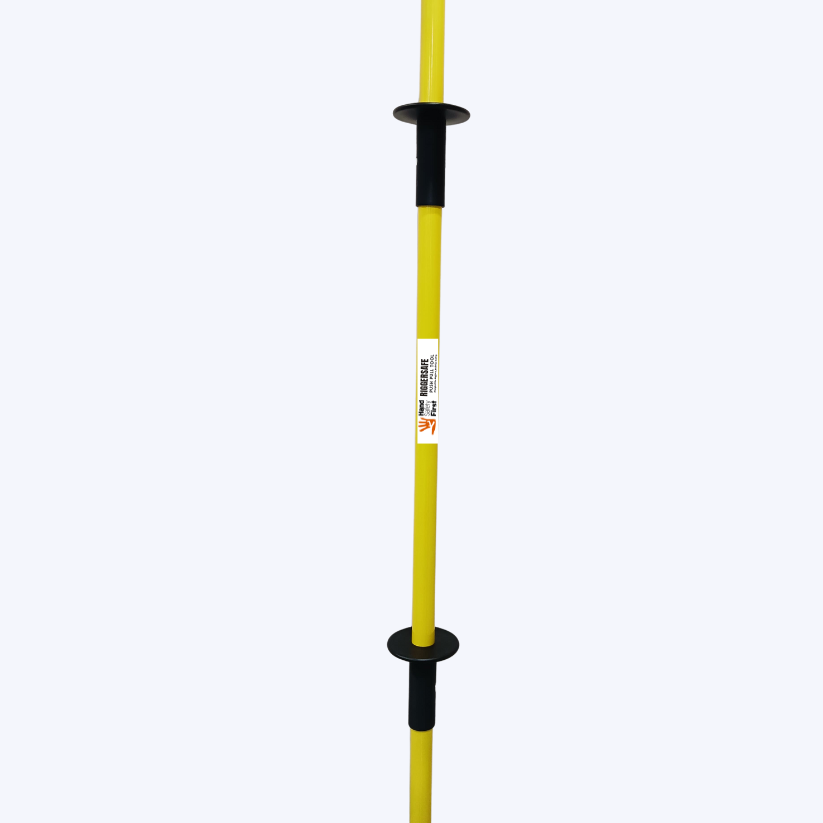

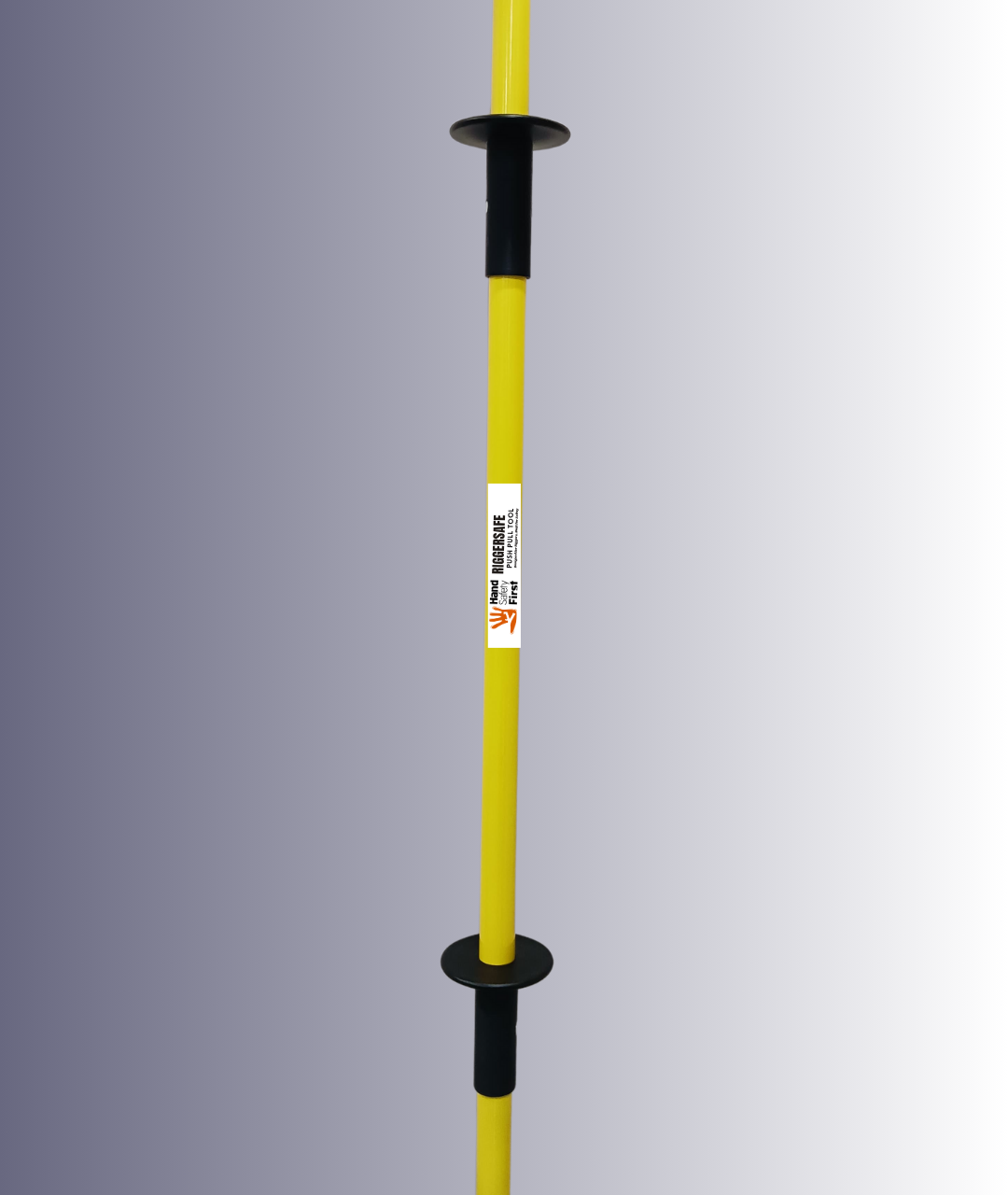

Durable Fibreglass Construction

Industrial-strength, non-conductive, and corrosion-resistant shaft.

Wide Rubberized Push Head

6" face ensures effective contact with pipes, beams, crates, and machinery.

Ergonomic D-Handle + Hand Guard

Designed to reduce fatigue and improve grip safety during prolonged use.

High-Visibility Finish

Safety yellow coating stands out in low-light or congested work zones.

Chemical & Weather Resistant

Built to withstand oils, salt spray, extreme cold or heat.

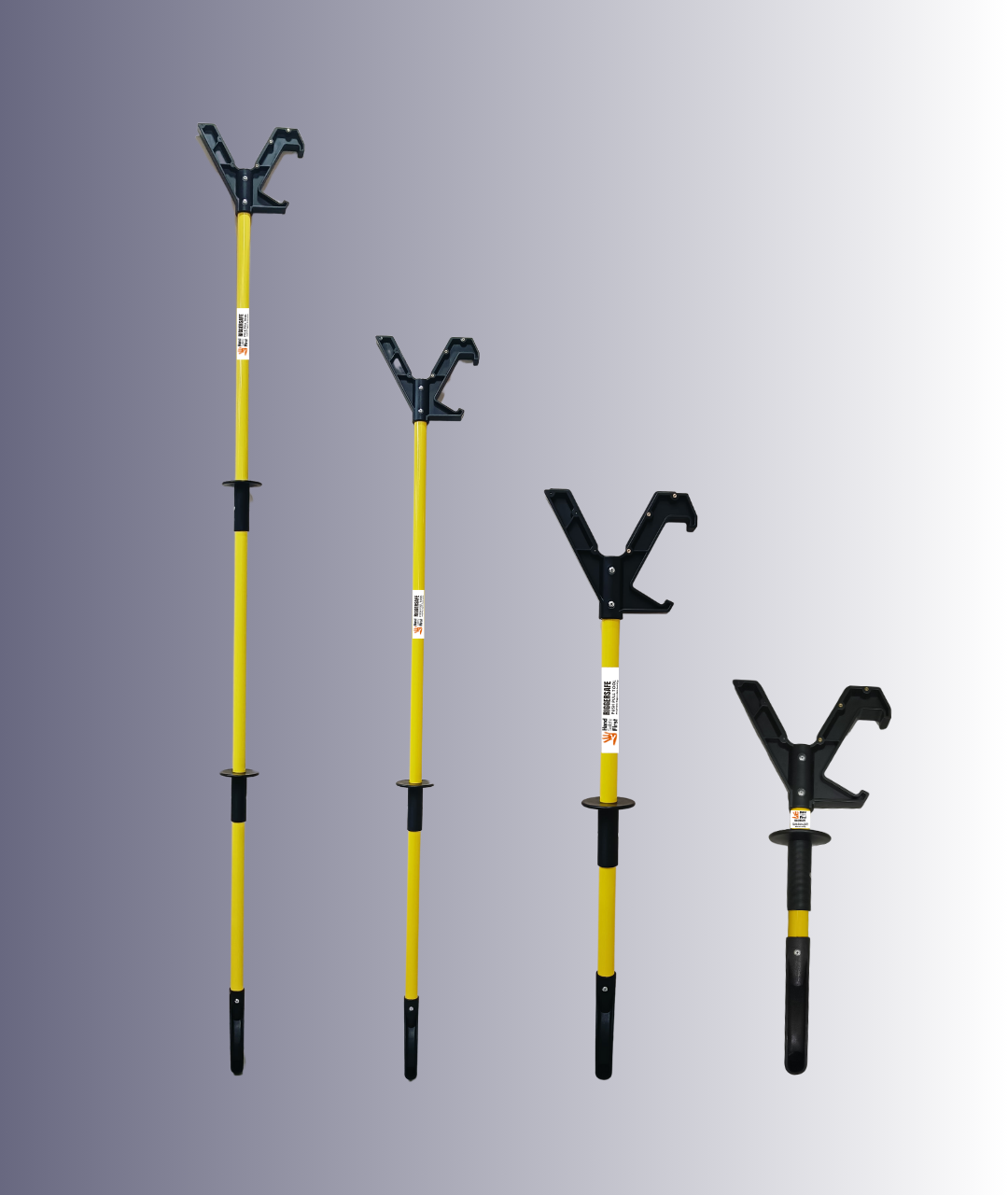

Tool Length Options

Available in 4 ft, 6 ft, and 8 ft sizes for various reach requirements.

Applications of

HSF RiggerSafe – Hands-Off Load Control Stick

Oilfield rigging operations – Safe control of swinging hooks, slings, or suspended drill pipes

Wind turbine maintenance – Align blades, towers, and components from a safe distance

Construction & precast handling – Push or position concrete forms, beams, or rebar cages

Shipyards & marine decks – Move chains, lines, and suspended cargo without risking hand injury

Electrical & utility crews – Guide transformers, poles, or insulators while avoiding electrical risk

Mining and heavy machinery – Safely interact with oversized or awkward loads in dusty environments

Technical Specifications of

HSF RiggerSafe – Hands-Off Load Control Stick

- Product Name: HSF RiggerSafe – Hands-Off Load Control Stick

- Shaft Material: Heavy-duty, high-strength Fibreglass

- Lengths Available: 4 ft / 6 ft / 8 ft

- Push Head Width: 6 inches

- Total Tool Weight: 2.5 – 4.5 lbs (depending on length)

- Handle Type: Ergonomic D-handle with safety stop

- Temperature Tolerance: -40°C to +60°C

- Finish: High-Visibility Yellow (UV-resistant coating)

- Maintenance : Minimal (wipe clean, store dry )

HSF RiggerSafe Push Pull Tools Colors – Technical Purpose

Precision Blue – HSF RiggerSafe Push Pull Tools

The HSF RiggerSafe Push Pull Tools in Precision Blue is designed for technicians who require pinpoint accuracy when aligning and controlling suspended or rolling loads. Blue offers high contrast in bright deck environments and against structural steel, allowing operators to maintain visual focus.

- Use Case: Offshore drill floor alignment, precision positioning of valves and pipe joints.

- Technical Benefit: Enhances operator accuracy during fine load adjustments, reducing misalignment errors.

- Industries: Oil & Gas, Shipbuilding, Marine Cargo.

Safety Green – HSF RiggerSafe Push Pull Tools

The HSF RiggerSafe Push Pull Tools in Safety Green is ideal for plant environments, chemical facilities, and utility zones where green signals “safety” and high visibility is crucial. Green tools stand out in indoor and confined-space conditions.

- Use Case: Plant maintenance, refinery equipment positioning, power utility handling.

- Technical Benefit: Safety visibility in high-clutter industrial plants; reduces misplacement and tool confusion.

- Industries: Petrochemical Plants, Utilities, Refineries.

Bright Yellow – HSF RiggerSafe Push Pull Tools

The HSF RiggerSafe Push Pull Tools in Bright Yellow is the flagship safety leader’s tool. Yellow is universally recognized as the highest visibility color, making it ideal for open yards, steel fabrication shops, and offshore decks.

- Use Case: Crane lifts, module installations, heavy construction projects.

- Technical Benefit: Maximum contrast visibility ensures supervisors and riggers maintain tool sightline at all times.

- Industries: Offshore, Civil Construction, Steel Fabrication.

HSF RiggerSafe Push Pull Tools Sizes – Detailed Technical Applications

21” HSF RiggerSafe Push Pull Tools

- Application: Confined-space rigging, subsea modules, maintenance inside vessels.

- Technical Advantage: Ultra-compact, giving operators fingertip precision in areas where standard tools cannot be maneuvered.

24” HSF RiggerSafe Push Pull Tools

- Application: Mechanical rooms, utility vaults, small load adjustments.

- Technical Advantage: Adds slight reach over the 21” model while maintaining compact form for technician-level control.

36” HSF RiggerSafe Push Pull Tools

- Application: Rig floor drill pipe guiding, steel fabrication yards, marine decks.

- Technical Advantage: Provides balance between control and distance, suitable for medium load handling.

42” HSF RiggerSafe Push Pull Tools

- Application: Offshore cargo handling, crane-assisted pipe lifts.

- Technical Advantage: Delivers additional leverage for maneuvering heavy suspended loads without close proximity.

48” HSF RiggerSafe Push Pull Tools

- Application: Structural construction, prefabricated component handling.

- Technical Advantage: Provides extended distance for safer handling while retaining operational maneuverability.

50” HSF RiggerSafe Push Pull Tools

- Application: Pipeline yards, large valve positioning, onshore rigging.

- Technical Advantage: Unique mid-size tool offering extended torque control for pipe bundle management.

60” HSF RiggerSafe Push Pull Tools

- Application: Offshore platforms, ship decks, large-scale rigging setups.

- Technical Advantage: Longer safety distance while maintaining controlled handling in dynamic lifting zones.

72” HSF RiggerSafe Push Pull Tools

- Application: Cargo handling, offshore crane operations, marine load transfers.

- Technical Advantage: Long reach provides maximum distance from heavy swinging loads, reducing operator risk.

96” HSF RiggerSafe Push Pull Tools

- Application: Extreme offshore environments, bulk cargo, and high-risk lifts.

- Technical Advantage: Maximum operator clearance, ensuring hands never enter pinch zones during dangerous suspended load operations.

Benefits of Using the HSF RiggerSafe Stick

- Protects Hands & Fingers from crush, pinch, and impact injuries

- Boosts Load Control in tight spaces, at height, or near moving machinery

- Improves Compliance with hands-free and safety protocols

- Reduces Strain & Fatigue with lightweight and ergonomic design

- Minimizes Downtime due to injuries or unsafe rigging practices

- Built for Harsh Environments and industrial use—won’t rot, rust, or conduct electricity

Who Should Use the

HSF RiggerSafe – Hands-Off Load Control Stick?

This tool is trusted by professionals in:

- Oil & Gas

- Renewable Energy (Wind, Solar)

- Heavy Civil Construction

- Marine & Shipbuilding

- Utilities & Infrastructure Maintenance

- Mining & Fabrication Yards

Why Choose

HSF RiggerSafe – Hands-Off Load Control Stick?

When safety and control matter most, the HSF RiggerSafe – Hands-Off Load Control Stick delivers. Engineered for professionals who refuse to compromise on workplace safety, this rugged, precision-built tool helps your crew maintain full control over suspended or moving loads—without risking hand or finger injuries.

With its non-conductive fibreglass shaft, ergonomic grip, and high-visibility finish, the HSF RiggerSafe – Hands-Off Load Control Stick offers the strength and stability of direct contact, while promoting a 100% hands-free rigging culture.

From oil rigs to wind farms, and from shipyards to heavy construction zones, RiggerSafe is the smart, safe choice for load-handling operations where efficiency, durability, and injury prevention are non-negotiable.

Put safety first. Choose the HSF RiggerSafe – Hands-Off Load Control Stick.

What Our Users Say

HSF RiggerSafe – Hands-Off Load Control Stick?

1. “RiggerSafe has completely changed how we approach suspended load handling on our offshore platforms. It's lightweight, easy to control, and most importantly—it keeps our guys' hands away from danger zones. We now mandate it for all rigging operations.”

— Vikram S., Rig Supervisor, Offshore Oil & Gas

2.“We started using the HSF RiggerSafe Load Control Stick on our wind turbine projects, and it's been a game changer. Whether we’re aligning nacelle components or guiding blades into position, it gives our crew the confidence and control they need—without the risk.”

— Anika R., Site Engineer, Renewable Energy (Wind)

3. “I’ve worked in industrial fabrication for over 15 years, and this is hands down the most practical tool for hands-free rigging I’ve used. It’s durable, easy to clean, and fits perfectly into our safety-first workflow.”

— Ramesh T., Safety Officer, Fabrication Yard

4. “Using RiggerSafe during maintenance of high-voltage equipment helped us improve compliance with our hands-free policy. The fibreglass shaft and high-visibility finish made it an instant win with our safety auditors.”

— Deepak M., Utility Maintenance Manager, Power Sector

Usage support

Safe Load Positioning Guidelines: Industry DOs & DON’Ts Using RiggerSafe

UNIVERSAL SAFETY PRINCIPLES (Applicable to All Industries)

✅ DO

- Use the RiggerSafe only to guide, push, pull, or align loads.

- Maintain minimum 600 mm (2 ft) hand clearance from the load at all times.

- Apply force smoothly and in line with load movement.

- Ensure the crane/hoist carries 100% of the load weight.

- Maintain clear line of sight with the load and crane operator.

- Inspect tool condition before each shift (shaft, head, handle, coating).

❌ DON’T

- Never use RiggerSafe to lift, support, arrest, or stop load weight.

- Do not hook, tie, or trap the tool into slings, shackles, or rigging gear.

- Do not side-load, twist, or jerk the tool.

- Never step into the swing radius of a suspended load.

- Do not use damaged, cracked, or deformed tools.

1️⃣ OIL & GAS / PETROCHEMICAL INDUSTRY

Typical Risks

- Pipe roll-over

- Sudden center-of-gravity (COG) shift

- Slippery surfaces (oil, grease)

- Congested pipe racks

✅ DO

- Use longer lengths (6–8 ft) to maintain distance during pipe spool alignment.

- Position the tool below COG when guiding round loads.

- Anticipate load rotation as slings slacken during landing.

- Coordinate tool movement with standard crane hand signals.

- Use RiggerSafe during final 300 mm positioning, not bare hands.

❌ DON’T

- Don’t try to stop a rolling pipe with body weight or foot.

- Don’t guide loads while standing on oily or uneven grating.

- Don’t push perpendicular to pipe axis—this causes spin.

- Never reach between pipe and rack for “last-inch” adjustment.

Make a Rule™

No hand on suspended pipes, valves, or spools—RiggerSafe only.

2️⃣ POWER PLANTS (THERMAL, HYDRO, NUCLEAR)

Typical Risks

- Tight clearances

- High-value precision equipment

- Crush zones near foundations

✅ DO

- Use controlled micro-movements during turbine, generator, or pump alignment.

- Keep tool face square to the load for predictable movement.

- Maintain communication with lift supervisor during critical placement.

- Use RiggerSafe during grouting and foundation seating stages.

❌ DON’T

- Don’t force alignment if resistance is felt—signal crane instead.

- Don’t place hands under base plates or skids.

- Don’t guide loads while standing between fixed structure and suspended equipment.

HSC Note:

Most hand injuries occur when load touches down—this is mandatory RiggerSafe zone.

3️⃣ CONSTRUCTION & PRECAST YARDS

Typical Risks

- Swinging concrete elements

- Rebar pinch points

- Uneven ground

✅ DO

- Use RiggerSafe to control swing before landing, not after.

- Stand outside drop zone while guiding beams or panels.

- Guide rebar cages from ends—not mid-span.

- Use high-visibility color tools for site awareness.

❌ DON’T

- Don’t push concrete elements while standing downhill.

- Don’t place hands between beam and column face.

- Don’t attempt to “catch” a drifting load manually.

Site Rule:

If hands go inside the load envelope → STOP the lift.

4️⃣ MARINE, SHIPYARDS & OFFSHORE PLATFORMS

Typical Risks

- Wind-induced load drift

- Vessel motion

- Wet, slippery decks

✅ DO

- Use long-reach tools (6–8 ft) to counter wind drift safely.

- Apply force gradually, accounting for vessel movement.

- Maintain three-point footing before engaging load.

- Keep body positioned upwind of the load.

❌ DON’T

- Don’t fight wind force manually.

- Don’t stand between load and bulwark or structure.

- Don’t over-correct swinging cargo—small inputs only.

Critical Offshore Rule:

If you need body weight → the lift setup is wrong.

5️⃣ WIND ENERGY (TOWERS, BLADES, NACELLES)

Typical Risks

- High elevation

- Long, flexible components

- Precision alignment needs

✅ DO

- Use RiggerSafe for fine angular alignment, not force correction.

- Maintain tool engagement at blade root or reinforced points.

- Keep hands outside blade sweep area at all times.

❌ DON’T

- Don’t guide blades by grabbing leading/trailing edges.

- Don’t position hands near flange bolt holes.

- Don’t attempt correction during sudden gusts—pause the lift.

6️⃣ MINING & HEAVY MACHINERY

Typical Risks

- Oversized components

- Poor visibility

- Dust and vibration

✅ DO

- Use longer tools to maintain clearance from awkward geometries.

- Apply force only when load is stable and controlled.

- Keep escape path clear before engaging load.

❌ DON’T

- Don’t stand inside machine articulation zones.

- Don’t use RiggerSafe as a pry bar or lever.

- Don’t work under suspended equipment during maintenance.

Push–Pull Tools for Riggers – FAQ

1. What is a push–pull tool actually for?

A push–pull tool is used to move, guide, or line up a load without putting your hands near it.

Simple rule:

- Crane takes the weight

- Tool controls the direction

- Hands stay clear

It is not meant for lifting or holding load weight.

2. Can a push–pull tool take load like a sling or shackle?

No. Never.

Push–pull tools are not load-rated lifting gear.

If you try to hold weight with it:

- Load can jump

- Tool can slip

- Hands and body get pulled into danger

3. Why does centre of gravity matter when using a push–pull tool?

Every load wants to turn toward its heavy side.

If you push or pull without thinking about COG:

- Load can spin suddenly

- Fingers get trapped

- Tool loses contact

Always think:

“Which way will this load move when it touches down?”

4. How should force be applied with a push–pull tool?

Straight and smooth.

Do:

- Push or pull in the direction you want the load to move

- Use small movements

Don’t:

- Yank

- Twist

- Side-load the tool

If it’s not moving — don’t force it.

5. How much force is too much force?

If you’re using your body weight or straining, it’s already too much.

Correct action:

- Stop

- Signal the crane

- Adjust the lift

Remember:

If the crane isn’t doing the work, something’s wrong.

6. Does surface condition matter?

Yes — a lot.

For magnetic tools:

- Best on clean steel

- Oil, paint, rust, or scale reduces grip

- For hook or claw tools:

- Better for painted, oily, or odd-shaped loads

Wrong tool + wrong surface = loss of control.

7. Why does tool angle matter?

Magnetic tools hold best when they sit flat on the load.

If the tool is tilted:

- Magnet strength drops

- Tool can pop off suddenly

Always square the tool before applying force.

8. How close should hands be to the load?

Hands should stay at least 2 feet (600 mm) away.

Inside that zone:

- Loads shift

- Fingers get crushed

Only the tool goes in. Never your hands.

9. Can I use a push–pull tool on a suspended load?

Yes — only to guide it.

Conditions:

- Load fully on the crane

- Tool not hooked to slings or shackles

- You stay out of the swing path

Never try to stop or hold a swinging load.

10. When do most hand injuries happen?

Right at landing.

When:

- Load touches down

- Slings go slack

- Load shifts unexpectedly

That’s when people reach in with fingers.

Use the tool instead.

11. Can a push–pull tool touch slings or rigging gear?

No.

Never:

- Hook it on slings

- Rest it on shackles

- Use it like rigging equipment

It’s a hand safety tool, nothing else.

12. What site conditions make push–pull tool use more risky?

Watch out for:

- Wind pushing the load

- Slippery or uneven ground

- Oil or grease underfoot

If your footing isn’t solid, don’t apply force.

13. What should I check before using a push–pull tool?

Quick checks:

- Handle not cracked or bent

- Magnet clean and solid

- Hook not worn or opened

If it looks damaged — don’t use it.

14. How do push–pull tools usually fail?

Common problems:

- Magnet slips due to dirt or angle

- Tool kicks back from over-force

- Rigger loses balance

All of these come from rushing or forcing the job.

15. Why are push–pull tools pushed so hard in safety rules?

Because they:

- Keep hands out of danger

- Remove guesswork

- Work the same way every time

Hands make mistakes. Tools don’t.