Hand Safety First

Slidesledge

Slidesledge

Heavy-duty slidesledges designed for safe and efficient handling of heavy materials and equipment.

Share

Description

Introduction to Slidesledge Hammers

As impact tools, traditional chisels and hammers are among the most dangerous tools, often causing injuries due to blows from slidesledge hammers .

Workplace accidents involving traditional power hammers and shears account for 10 to 18 percent of all injuries, affecting the arms, chest, neck and head.

A great alternative to the traditional hammer and chisel. 100% Made in the USA.

Operate the tool with one hand. Ensure precise impact and increase the safety and efficiency of impact work. It is driven by sliding a steel drive bar back and forth, reducing effort and increasing safety.

Among other hands-free safety tool innovations, the slidesledge hammer offers controlled operation, increased safety, precision and can be operated by one person instead of two, reducing the overall risk percentage.

Fingers are susceptible to crushing when using a hammer. Use FingerSaver to improve overall finger safety with a hands-free app.

Multi-headed sliding hammers are essential for the maintenance and repair of heavy equipment. Prevent hand injuries by eliminating the use of dangerous traditional slidesledge hammers.

Part no - HSF-SS

What is a Slidesledge mass used for?

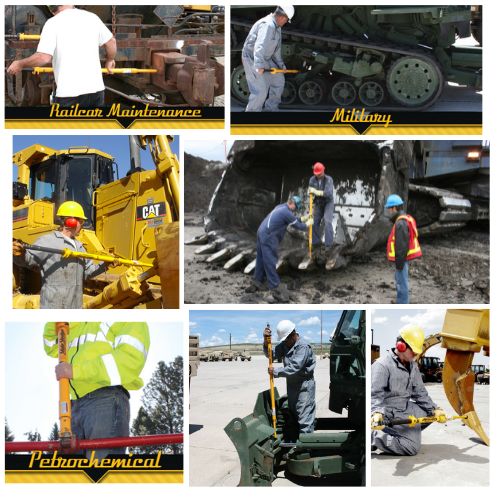

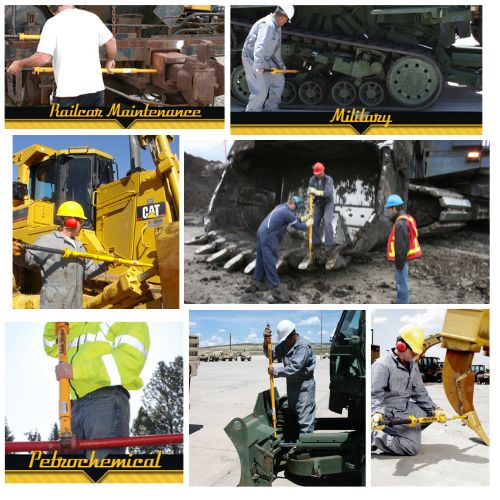

Applications for a slidesledge hammer include several heavy-duty maintenance tasks where a heavy-duty hammer is useful.

Generally, any task involves handling and manipulating tire beads, replacing bushings/bearings/seal plates, removing rusted and non-functional pins, removing pins from bucket teeth, tightening or loosening bolts, inserting between ripper teeth, etc.

Below are more detailed tasks.

A detailed overview of the practical uses of the slidesledge hammer.

Construction

• Automotive, locomotive, hydrodynamics

• Onshore and offshore drilling platforms

• Petrochemical industry

• Mining hammer

• Railway

• Agriculture

• Military

Function

The tool has a straight design with a relatively long handle attached to various pins to ensure precision. The practical difference with this tool is that it amplifies the impact force and maneuverability of the slidesledge hammer, while creating a buffer area that keeps your hand and fingers away from the operating area in case you miss a blow that can result in injury with a slidesledge hammer.

A precision slidesledge hammer, the tool is driven by a central bar that pulls back and forth and can be fitted with a variety of head attachments, including interchangeable upsets and quick-change tips designed specifically to remove track pins and sprocket bolts, allowing easy access to hard-to-reach pins.

The drive bar also increases precision and efficiency of use, while the tool's dead-centre steering reduces overall energy requirements.

In addition to improved safety, the tool also provides additional functional precision to prevent destruction or damage to equipment in the event of a mishandled maneuver or oblique attack.

Designed to provide contact-free safety when using impact tools, the Hammer Tight Key Lock features a thread lock that safely replaces manual application.

Features and Types of Slidesledge

Slidesledge hammers offer several enhancements to increase efficiency during various tasks.

There are three common design categories: multi-head inertia hammers, inertia pull hammers, inertia hammers, and inertia precision hammers.

The dimensions of the slidesledge hammer very accordingly and each innovative tool consists of common compartments.

The main parts of a slidesledge hammer include:

Drive shaft; Slidesledge hammer handle designed not only for an extended buffer zone and safety measures when using a slidesledge hammer, but also with improved functionality and maneuverability

Slidesledge - Part Numbers

HSF-SS

Replacement tips

Multi-headed hammers are widely used in many industries.They accommodate a range of mass impact forces, have interchangeable pin guides to access hard-to-reach surfaces, and are often used to handle high-load, power-intensive tasks.

In a nutshell

The traditional slidesledge hammer and chisel are potentially one of the most dangerous and difficult tools to operate.

Instead of this high-risk tool, modern tool innovation has introduced slidesledge hammers that meet the highest standards and are entirely made in the USA.

The idea behind this innovation is to reduce the force required, the time spent, as well as operator strain and hammer injuries.

The safest hammer includes the high -quality accuracy and high -quality distribution of various inserts in pincodes by removing a fairly complex pole of the fork and the conductor joint.

Here, HAND SAFETY provides the correct decision on all the work environments for two general reasons.It supports the principles of safety of worker experts and enhances mechanical and physical task efficiency.

Increase the profitability of:

1. Eliminate special equipment or additional operator using specific tasks, therefore

2. One of a person's operations and

3. Time hours are reduced to a minimum

Simplifies maintenance / repair in the field:

1. Do and install a PIN code on any type of field equipment

2. Read bolts and rusty scissors in a few seconds

3. Crossed between the bucket teeth for the removal and installation of the light

4. Adaptation to fork separators for rapid and light transitions

Promotes a safer working environment:

1. Manages the operator's efforts and the risk of injury

2. Measures muscle tension

3. Diminshina flying garbage associated with a hammer and a chisel

Adapts to many applications

1. Reporters with interchangeable applications that allow a tool to carry out the task of many

2. Adaptation to a quick change of advice

Provides a powerful and precise effect

1. Created from hardened steel with a long lifespan

2. Maximum impact power (18,000 pounds per square inch)

3. You can use the additional weight of a 5 -pound hammer for additional exposure effects.